Classification and advantages of melt screen changer for extruder

Batte domestic brand exchange machine manufacturers, providing professional net exchanger, including: melt blown non-woven fabric special screen changer, film special non-stop switching device, pipe industry and special pipe exchanger special pipe, fully meet the needs of the user production, to achieve non stop, no leakage of high efficiency production operation.

The classification of new polymer melt screen changer for extruder can be classified into four categories according to main functions.

1, long effect net screen changer: the filter net area of this kind of net exchanger is 5-50 times larger than that of the old type, and the continuous working time of each mesh can basically increase the same multiplier, but the flange still needs to be dismantled.

2, fast changing net switch: when changing the net, the filter net is replaced quickly by the liquid pneumatic device, and this kind of net exchanger usually needs stopping operation. The advantage is that it does not need to disassemble the machine and shortens the time of stop.

3, non stop switching net screen changer: this kind of net exchanger can replace the filter without interrupting the normal production, increasing production, energy saving and no waste, especially in the long process and high efficiency production line.

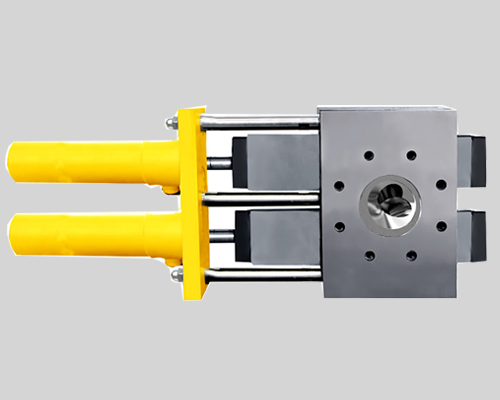

4. Multi-function screen changer: it has many functions such as non-stop switching, long effect filter or reverse flushing filter. It is the direction of research and development of polymer melt exchanger. In addition, according to the shape of the filter carrier, a new type of mesh changer can be divided into disc type, sliding plate type and plunger type. According to the operation mode, new type of mesh changer can be divided into manual, mechanical, hydraulic, pneumatic and automatic. In addition, it can also be classified according to the type, shape and number of channels.