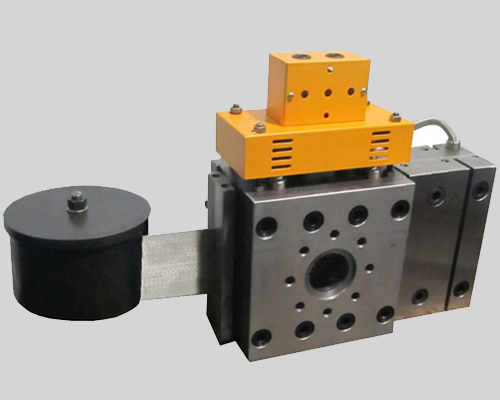

Introduction of New Type Continuous screen changer

Some rigid PVC processors do not use filters because PVC is easy to differentiate, especially when touched with steel or copper at high temperatures (differentiation temperature 200 degrees). Filtration screen will increase the temperature of polyvinyl chloride melt material and easily degrade, which requires materials with better thermal stability, thus adding the cost of data. If the special filter converter for PVC is used, the cost will also be added.

The existing production of new type of network screen changer uses the principle of hydraulic rapid active network screen changer. A series of net changers, such as hydraulic active net changer, new compensating sealed net screen changer, double column net changer, double plate net changer, new connected net changer and new pulse brush net changer, were selected to thoroughly deal with the irregular situation of products caused by the unstable material pressure during the shutdown of extruder and net changer. Particularly suitable for granulation, pipe, sheet, sheet, EPE, EPS Pearl cotton, XPS extrusion board, PVB anti-riot film, hollow board, extrusion net, BOPET/BOPP chemical fiber long and short fibers. It is used for drawing (single filament, flat filament, fishing net) goods, etc. Secondly, because of the skill of screen changer based on the principle of active rapid screen change, the screen is easy to clean and replace the simple screen without much obstruction. When changing the screen, the pressure, material flow and material temperature are more stable, which thoroughly deals with the appearance that the high temperature of the screen increases the temperature of the melting material of polyvinyl chloride and makes it easy to degrade, thus dealing with the worries of the producers of polyvinyl chloride.

More about screen changer products:

Batte is a professional screen changer manufacturer, supplying screen changer, especially screen changer for extrusion mould