Screen Changer Helps Recycle Dirty Scrap

Are you looking for the information of Screen Changers | Recycling Equipment for Preprocessing?

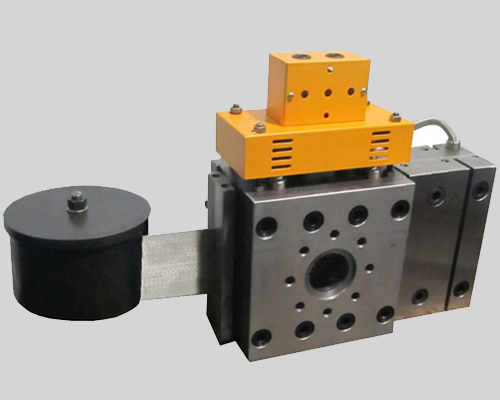

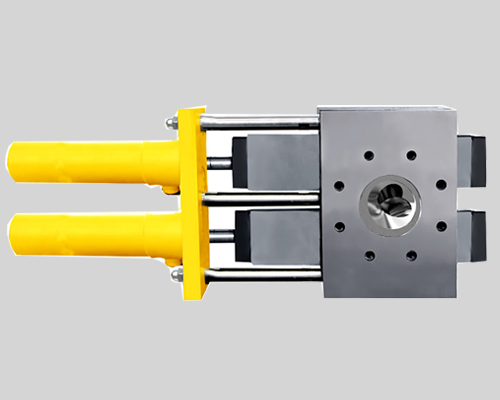

Screen changers represent an active and highly competitive segment of the plastics machinery industry. Nevertheless, one source recently asserted that there hasn’t been anything new in the technology for 40 years. This statement ignores an important fact: Though they are usually small with respect to the rest of the equipment in the line, screen changers serve an extremely important function in recycling. The systems collect and dispose of contaminants, both to protect the equipment in the line, and to ensure the purity of the product.

Screen changers are available through original equipment manufacturers, as well as through integrators — extrusion line designers who do not manufacture the units. Processors’ challenges vary, so screen changers deliver different benefits, depending on the situation.

PRI’s Shaw reports that its screening equipment could no longer handle the levels of contamination and variability in incoming materials. The company, which recycles PS, PP and PE, tried back flush, but decided the ERF would perform better. It was important to PRI that it could process materials with impurity levels of as much as 5 percent from contaminants such as paper, foil and PET. Folded, frayed or broken screen packs are now a thing of the past.