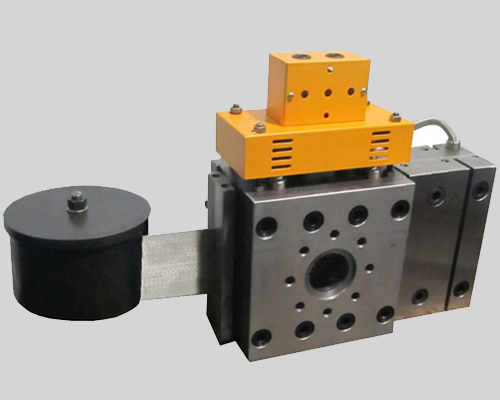

Plastic recycling screen changer

Abstract: plastic recycling screen changer in the extrusion process, the plastic melting plastic, heat, the melt will have decomposition residues, together with the impurities in the raw materials, if not clear, will lead to blockage flow, products Defective, and even shutdown production.

Plastic recycling screen changer in the extrusion process, the plastic melt plasticized, heated, the melt will have decomposition residues, together with the impurities in raw materials, if not removed, will lead to blockage flow path, the product defects , And even shut down production. In order to filter out the debris, the recycle screen changer needs to set a filter between the screw head of the plastic recovery granulator and the molding head. But with the extension of the extrusion time, the network of debris gradually accumulated, resulting in increased nose pressure, flow decline, more than a certain pressure, the filter will be broken, failure, you must shut down for the filter.

The double-net-exchange plastic recycling pelletizer comprises a barrel and a sieve base, wherein the sieve base is connected with a motion executing component, which is a cylinder or a cylinder. After the barrel is extruded End with a front end cover and a rear end cover, the filter seat is arranged between the front end cover and the rear end cover, characterized in that the filter seat is provided with two filter holes in the filter hole Respectively, provided with a filter, cylinder or cylinder action makes filter meshing two filters to achieve interchange; the filter hole close to the front end of the cover than the diameter of the hole close to the rear cover to block the filter;

When the need to replace the filter, the cylinder or cylinder work, the push rod to push the filter seat, you can filter seat on the filter seat to idle work station, the replacement quickly, the cylinder or cylinder driving force, Does not require downtime, greatly improving production efficiency.