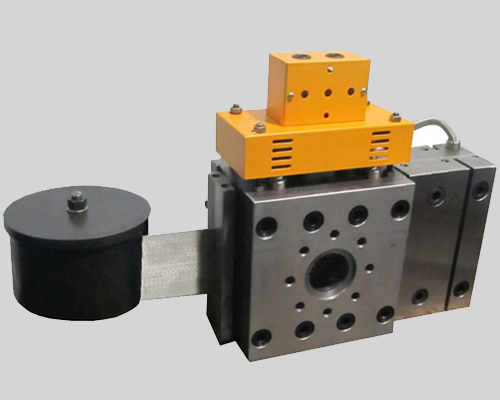

Backflush Screen Changer for recycled materials

Backflush Screen Changer for recycled materials Performance Characteristics:

1. the Asia batte Backflush Screen Changer for recycled materials--made in china have huge filtration area from 1700 cm² to 3600 cm², efficient filtration, stable production and excellent quality.

2.due to the very effective screen cleaning with high pressure impulses, its rate of the screen-cleaning exceeds 80% , repeated usage up to 100-400 times (depending on the filtration fineness), minimizing the screen cost.

3.eliminate busy operation in the process of filter calcinations, ultrasonic cleaning, chemical immersion, and save the cost of various cleaning equipment.

4.it has 100% availability of the production line while cleaning and replacing the screen, elimination of scraps.

5. low operation costs of production.

6. simple replacement, save time and labor.

7.major structure parts are made of high-quality alloy with high strength and high rigidity.

8.with abrasion resistance, long life.

Backflush Screen Changer for recycled materials Applications:

1. the Backflush Screen Changer for recycled materials has special utility in the recycling and granulation combined with high impurities, such as PE, PP, PS, ABS, PET, PA, etc.

2. making use of recycling materials and waste to process product directly; Absence of the process of granulation, preventing the material degradation and low costs for production. For example, directly process PET flake into film, sheet, strap, etc; directly process PS recycling particle into frame, XPS, IXPP foam, etc.

3. the filter is even applied in the process of medium and large production lines with the features of high precision filtration, large production flow, good stability, and high automation.